The Company

Profile

Founded in 1980, RECO Gesellschaft für Industriefilterregelung mbH is active as an independent company in the fields of electronic control systems and switchgear production. We are employer to more than 50 people in the areas design and development, administration and manufacturing.

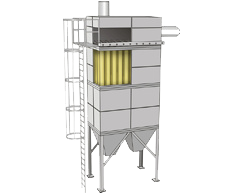

Our product portfolio includes electronic control systems and modules specifically designed for use in the fields air filtration and process technology. As a system provider and technology partner, we attach great value to the closest proximity to markets and customers for the development of future strategies and a quick implementation of innovations.

Our services

- Analysis of process requirements

- Creation of integrated concepts for the optimization of control environments

- Development of general and customer-specific control systems

- Production of electronic control systems, switchgear and valve equipment

- Commissioning and training by our service unit

- Sustainable support by our sales unit

Markets & Products

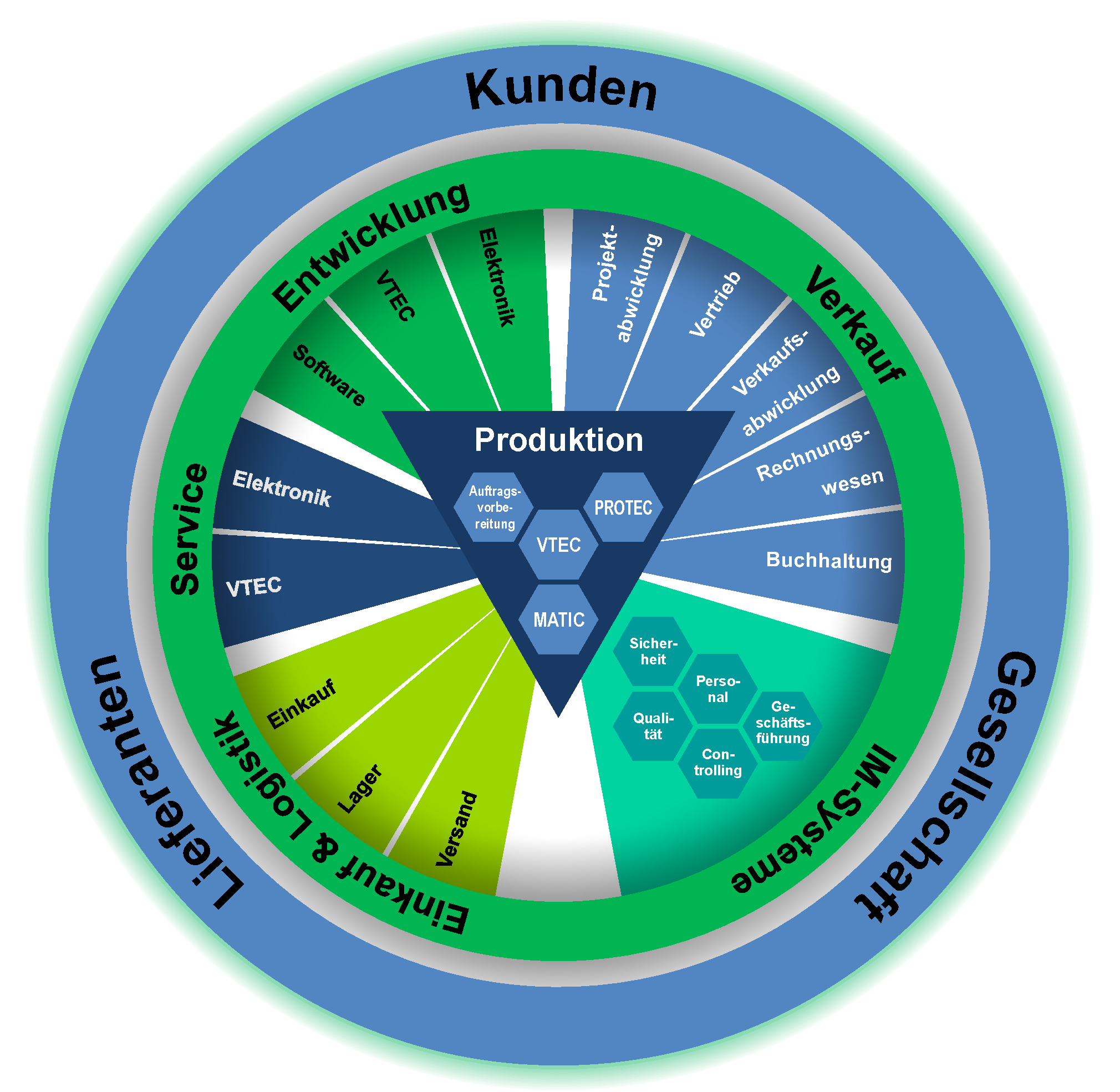

Our company is divided into three divisions whose activities result in an optimum of synergies and price-performance ratio for our products and distinguish ourselves as a system provider.

Every year, more than 30,000 industrial air and process control systems are equipped with RECO controls, switchgear and valve systems.

Our control systems are used all over the world for air pollution control, machinery engineering, producing industries, mining, pharma and food industries. We sell our products to plant and component manufacturers only.

Business fields: Control systems and measuring technology for dust filters, liquid filters, electrostatic precipitators, silo technology, pharma plants, pan coaters, pulverizing mills. General switchgear systems

Testing & Certifcation

All control systems made by RECO are tested and manufactured according to applicable standards. Our products are basically CEconform. Depending on requirements, we also carry out acceptance tests according to non-European standards such as cUL and GOST or for specific applications such as NEMA 4 or Germanischer Lloyd.

Our products designed for use in potential explosive atmospheres (ATEX zones) have been tested and certified by DEKRA-Exam.

Testing & CertifcationsCountry Regulations, Directives, Design codes & approvals

- AD-2000 (Germany/Europe)

- ATEX Directive 2014/34/EU

- DGRL 2014/68/EU

- GOST (Russia)

- TR CU 010 (EAC) (Eurasian Customs Union: Belarus, Kazakhstan, Russia etc.)

- TR CU 012 (EAC) (Eurasian Customs Union: Belarus, Kazakhstan, Russia etc.)

- TR CU 032 (EAC) (Eurasian Customs Union: Belarus, Kazakhstan, Russia etc.)

- DIN EN 60079-0 (Germany//Europe)

- DIN EN 60079-31(Germany//Europe)

- UL 61010-1 (US)

- CAN/CSA-C22.2 (US)

Certification:

- ISO 9001

- LR, DNV-GL, etc.

- TR-CU

Classification and Inspection Societies

- DNV-GL (Det Norske Veritas / Germanischer Lloyd)

- LR (Lloyd ́s Register)

- DEKRA EXAM

- TÜV (Technical Inspection Association )

Development

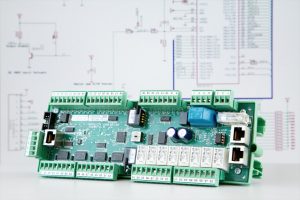

Hardware

We develop our products in-house – from the concept, wiring diagram up to the layout. Our products reflect more than 30 years experience. Layout and development are target-oriented to the specific requirements in industrial applications.

We use only components and materials that meet the requirements of their later application and our strict quality standards. Our own EMC testing laboratory, climatic chamber and advanced calculation programs are further prerequisites for target-oriented hardware developments from RECO.

Software

Also programming of our hardware is done in-house. Thanks to flexible functions and advanced technologies, even the most complex control processes are implemented efficiently. Operating and parameterization of our software modules are designed as dialog-based software with selectable language modules. RECO provides a free internet portal to our customers for customer-specific developments and program updates.

Our solutions are proven, reliable and easy to use.

Validation as per GAMP 4 is possible on request.

Design

The integration of mechanical and pneumatic components and modules in the concept of a control environment is becoming more and more important. Our goal is to provide comprehensive developments that go beyond control technology. We reduce costs by the use of integrated system components rather than individual components.

Based on this development policy, we have continually refined our product portfolio and now we have housing systems, keyboards with tactile keys, solenoid valve islands and cleaning systems for JET filters

Prototypes

Printed circuit board assembly for prototypes is done in-house. In this way, we can perform all tests that are crucial for serial manufacturing and application in the field, such as EMC measurements, already during the development stage.

For serial manufacturing, we have our electronic boards, assemblies and modules assembled by SMD technology.

Electronic control systems

RECOMATIC control systems

RECOMATIC control systems are designed for harsh industrial applications. The controllers and I/O modules are based on microcontroller systems with integrated EEPROM. On this basis, the programs can be loaded using any commercial PC. A two- or three-button menu navigation system guides the user consistently through the RECOMATIC control systems in all desired languages.

For networked applications in machinery and plant engineering RECO has developed their own data bus, the R-IMC-Bus (RECO Inter Module Communication Bus). It is based on an RS-485 interface with physical PROFIBUS connection. In this way, networking can be implemented within a control level using the much more cost-efficient R-IMC-Bus and only the connection to a higher-level control system requires a RECO PROFIBUS module with Profibus protocol.

On the last page of this brochure you will find a summary on the application fields for which the different RECO product lines are designed.

Instrumentation and control

For instrumentation and control, RECO provides a wide range of transmitters, controllers and sensor modules specifically designed for harsh environmental conditions and functions. Unit types equipped with microcontrollers can numerically process present signals and provide them via standardized interfaces or via the R-IMC-Bus. By a multi-point measuring method, a single transmitter can supply up to four different sensors and process signals from them. In this way, a central transmitter can save costly measuring inputs and individual components on higher-level control systems.

Customer-specific control systems

RECOMATIC control systems with their modular design, mechanical components and flexible programming are an outstanding platform for customer-specific control systems and functional islands.

Thanks to the compact design of electronic control units and the option to combine them with power components, control systems up to an output power of 7.5 kW can also be integrated in the RECO-Norm- Line housing systems as PCB solution.

All RECO front panels have the protection class IP 66 and are suited for the ATEX dust ex-zone 22 and particularly for switch panel mounting and machine control panels.

Please test us. We develop sustainable and economic solutions even for small quantities.

Switchgear systems

Design & Documentation

Our design and documentation for switchgear and machine control systems are based on European EN and international IEC standards. Design and manufacturing is done in-house – from standard switch cabinets in serial production, cUL-certified switch cabinets up to explosion- proof switch cabinets. We use the WS-CAD application and wiring diagram macros to create our documentation. Translations into all EU languages or other languages as requested by customers are available.

Switchgear systems with RECOMATIC control systems

RECOMATIC control systems and components for automation make it possible to implement machine control systems and complex switchgear for all applications and with a large operation depth. All control and regulation functions that are possible with PLCs are available. Moreover, RECOMATIC control units and I/O modules with R-IMCBus or Profibus allow a decentralized set-up of control components and their integration in process control systems

Special-purpose switchgear systems

We design and manufacture special-purpose switchgear systems for a variety of applications and environmental conditions. Our range includes systems for the fields below:

- Food and pharma with GAMP-4 validated software

- General machinery and plant engineering with GL approvals (Germanischer Lloyd) up to C3

- cUL certified switchgear systems

- ATEX-conform explosion-proof switchgear systems

- Switchgear systems for power plants

- Switchgear systems for underground plants

Standard switchgear units in serial manufacturing

For serial standard switchgear manufacturing, the RECOMATIC control program provides a wide range of control units and I/O modules for DIN rail and front panel mounting. By the use of RECO operation panels additional operating indicators, controls and visualization displays are not necessary to a great extent. Parameterizable program modules and the possibility to extend the functionalities by sensor modules allow applications in all areas of control and automation. In this way, it is possible to implement particularly cost-efficient and compact designs. Machining of mounting plates and housings on a machining center reduces manufacturing costs and helps to maintain a high level of quality.

Valve technology

RECO VTEC valve systems have been specifically designed for filtering separators with pressure pulse cleaning. Valves and purge gas tank systems complement our product range of RECOMATIC control systems with the goal of serving this market segment as a system provider.

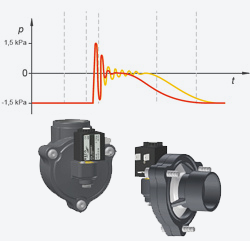

Solenoid valves

The development of powerful solenoid valves as a coupling element between control electronics and the mechanical part of the diaphragm valves is crucial for the implementation of short response times and effective opening times of the diaphragm valves. Specifically for this requirement, the solenoid valves with large and flow-optimized cross sections have been developed. The solenoid valves are designed for quick installation in enclosure systems, in particular for the RECO NormLine boxes. Thus, solenoid valves and electronic controls can be combined to compact control systems.

Diaphragm valves

Diaphragm valves for use in filter separators with pressure pulse cleaning excel especially by a very steep rise in pressure, a high KVvalue and a short closing time. These requirements are best realized through the new Power-Reflex diaphragms. For different applications, the diaphragm valves are available as angled diaphragm valves, through valves or valve modules

Purge gas tank systems

RECO through valves and valve modules combined with extruded aluminium sections being available in different diameters and shapes can be used to build purge tank systems. This combination allows us realize all required tank sizes and valve clearances. For the production of customized versions, the tools for the valve modules and extruded sections can be easily changed by changeable inserts.

Process management

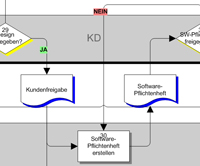

Holistic conisderation of business processes

Process management plays a central role at RECO. Because a company can only keep up its flexibility and competitiveness by ongoing improvement of its internal structures and processes.

So, RECO’s management system includes the essential elements of Lean Management and is based on the standards ISO 9001, ISO 14001, and TS16949 in their latest versions. However, quality and preservation of the environment are not only general principles that we represent to the outside world, but they are the basis of our selfconception. For this, our employees take centre stage and are not only means to an end. Their involvement in the ongoing improvement process has led to a high quality awareness and compliance with standards as a matter of course. An awareness that exceptions from specified work flows would cause high costs has been created.

Our consistent process orientation and efficient core processes in all business fields, from the administration to the dispatch, are the basis for any changes and extensions of our business. They enable us to

- Keep up our high quality requirements

- Have short throughput times and thus short delivery periods, and

- Have a consistent price structure

In this way, we can meet the requirements and expectations of our customers, suppliers, investors and employees apart from our own ambitions.

That is why process management is no luxury to us, but a must.

Quality policy

The name says it all:

RECO = REliability und COmpetence = Qualität

We need to be a reliable and competent partner to our customers and suppliers.

Reliability and competence are base values for our activities. Quality can only be achieved if we live and think according to these premises. Product reliability is as important as the reliability in a partnership between customer and supplier. In addition to the reliability being a basic requisite, we need to be a competent partner as well. Our customers and suppliers need to rely on our conduct.

“Everyone is customer and supplier as well”

Company policy = Quality policy:

Product orientation

Only if we can provide good products to our customers, we will be able to show our other qualities beyond this. Our aim is to develop products that

- Cover the customers’ application optimally from the technical point of view

- Result in an optimal overall cost situation for the customer

- Meet the high quality requirements

Customer orientation

Only if we are able to satisfy our customers permanently, our company will succeed in the long term. Our customers set the standard for the quality of our products and services. Their judgement about our quality is the decisive factor. We aim to

- Deliver high-quality products to our customers on time

- Advise and support our customers kindly and competently

Supplier orientation

Only if we involve our suppliers in our processes, we will be able to get high quality from them in the long term. High quality at long-term low costs has priority – always taking the overall cost situation into consideration.

Code of Conduct

We apply uniformly high standards of ethics and business conduct in every country in which we operate and in every business relationship. Anti-Corruption, Non- Discrimination, Safety & quality represent our basic values, anchored in our code of conduct.

Conflict Minerals Policy

RECO is working actively with its suppliers to ensure the responsible sourcing of conflict minerals from the DRC. For the simplified transfer of the information, RECO uses the Conflict Minerals Reporting Template created by the Electronic Industry Citizenship Coalition® (EICC®) and the Global e-Sustainability Initiative (GeSI). CFSI website: (www.conflictfreesourcing.org)

Environmental management

We strive to protect the environment on our own initiative and responsibility. The preservation of our natural environment and the basis of life for future generations, the safety of the workplace as well as the continuous improvement of work conditions in the work areas of the company, are of special concern to the management.

As a manufacturer of filter system components, we contribute essentially to the pure productivity of our customers. The environmental impact of each new activity, each new product and process are assessed in advance. Environmental awareness is promoted at all levels of the company through appropriate training. Our business partners are informed about our environmental policy and involved in our environmental activities.