Valves and tank systems for filtering separators

From the 3-D construction directly to the machining center –

new fully automatic production line in Troisdorf

The new RECO production line enables the transfer of engineering data directly to the machines. Optimized workflows ensure cost-effective and efficient order processing. With these investments, we have achieved our goal of being able to deliver every purge gas tank within 10 working days.

Customer-specific products can also be delivered within this production period. From the same profile different purge gas tank systems can be manufactured in one operation step.

- A new 15-meter-long machining center for different aluminum extruded profiles

- 5-axis profile machining center with an automatic clamping adjustment

- Parallel profile machining of two pieces up to 5 meter long with a cut optimization

- Simultaneous production of different flushing gas tank systems out of the same profile

- A new machining center with an automated bar loaders

- 2-spindle fully automatic machine with a part catcher

- Turning and milling for all RECO-adapters and valve inserts

- Upstream bar loader for computer-aided manufacturing in high quantities

Valve systems and flushing gas tank systems for filtering separators

The RECO VTEC valve systems were specially developed for filtering separators with pressure impulse cleaning. Various solenoid valves, diaphragm valves and complete purge gas tank systems of different dimensions are available for this application.

The purge gas tank systems meet the requirements of the Pressure Equipment Directive 2014/68 / EU and other international approvals. The RECO production of pressure equipment is monitored by the notified body DEKRA 2266 and is valid for module A1.

VR-DN 20 / -DN 25 / -DN 40 VS

90° angled diaphragm valves with TPE-E Power-Reflex diaphragm

- New flow-optimized design – more Power / higher weight rate of flow

- Valve body from aluminium

- with high pressure pulse

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Easy and flexible installation

- Valve control, pneumatically or electromagnetically 24 V DC / 110 V AC / 230 V AC

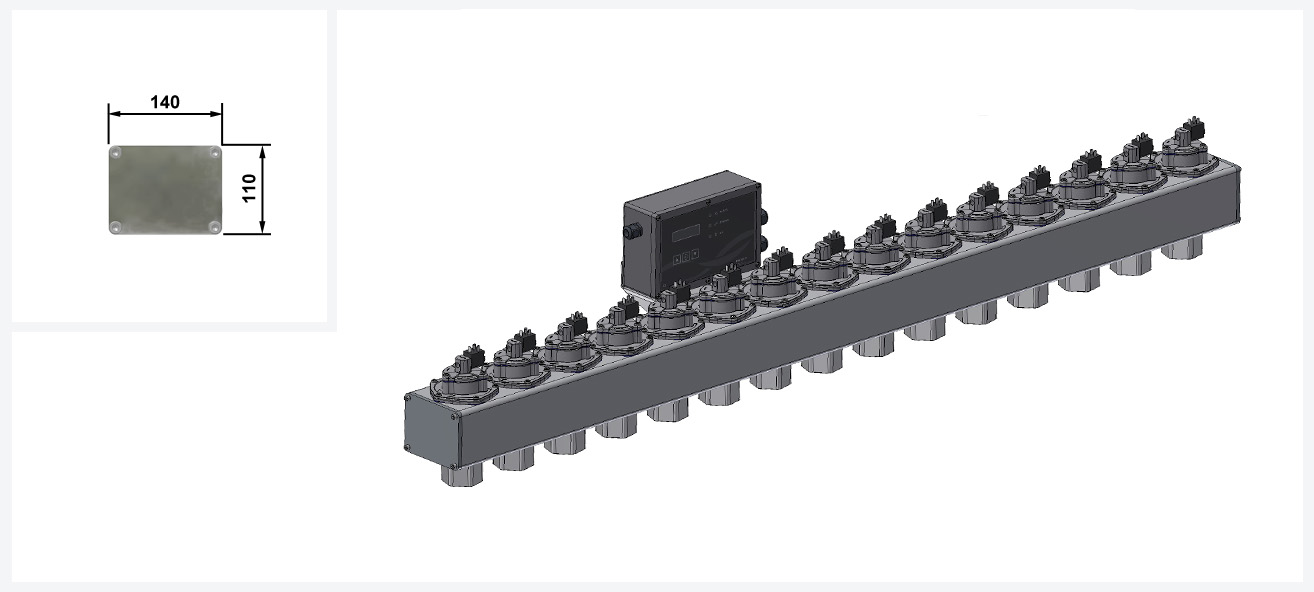

ST140/120-DN 40 VS

Purge gas tank system with integrated diaphragm valve, pilot operated

- Aluminium purge gas tank system according to pressure equipment directive 2014/68/EU

- with DN-25 pilot operation

- Design for through valves with variable valve spacing

- Very high pressure pulse through straight valve guide

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Filter controllers or valve boxes can be directly attached to the aluminium section

- 5000 mm maximum length of the aluminium section

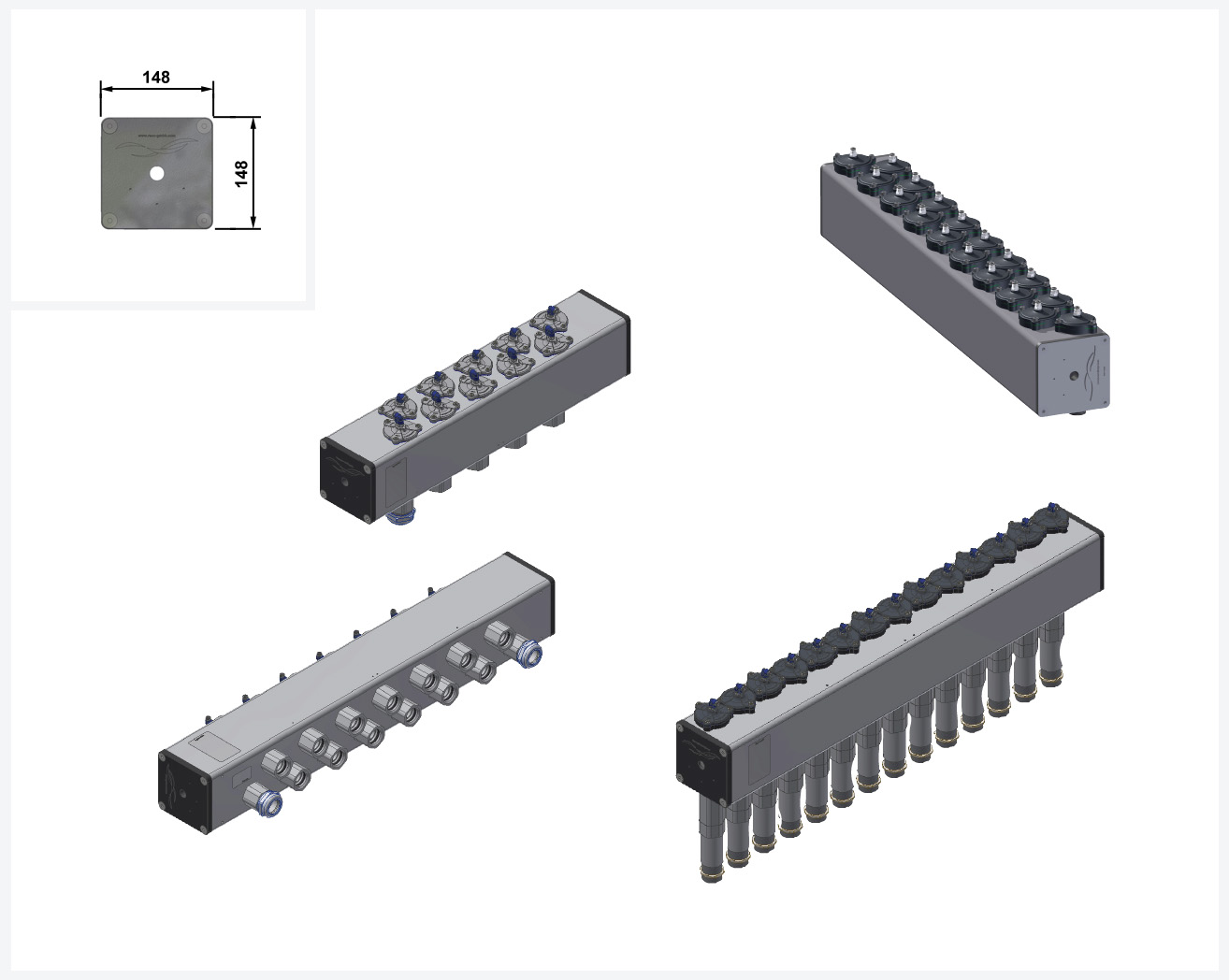

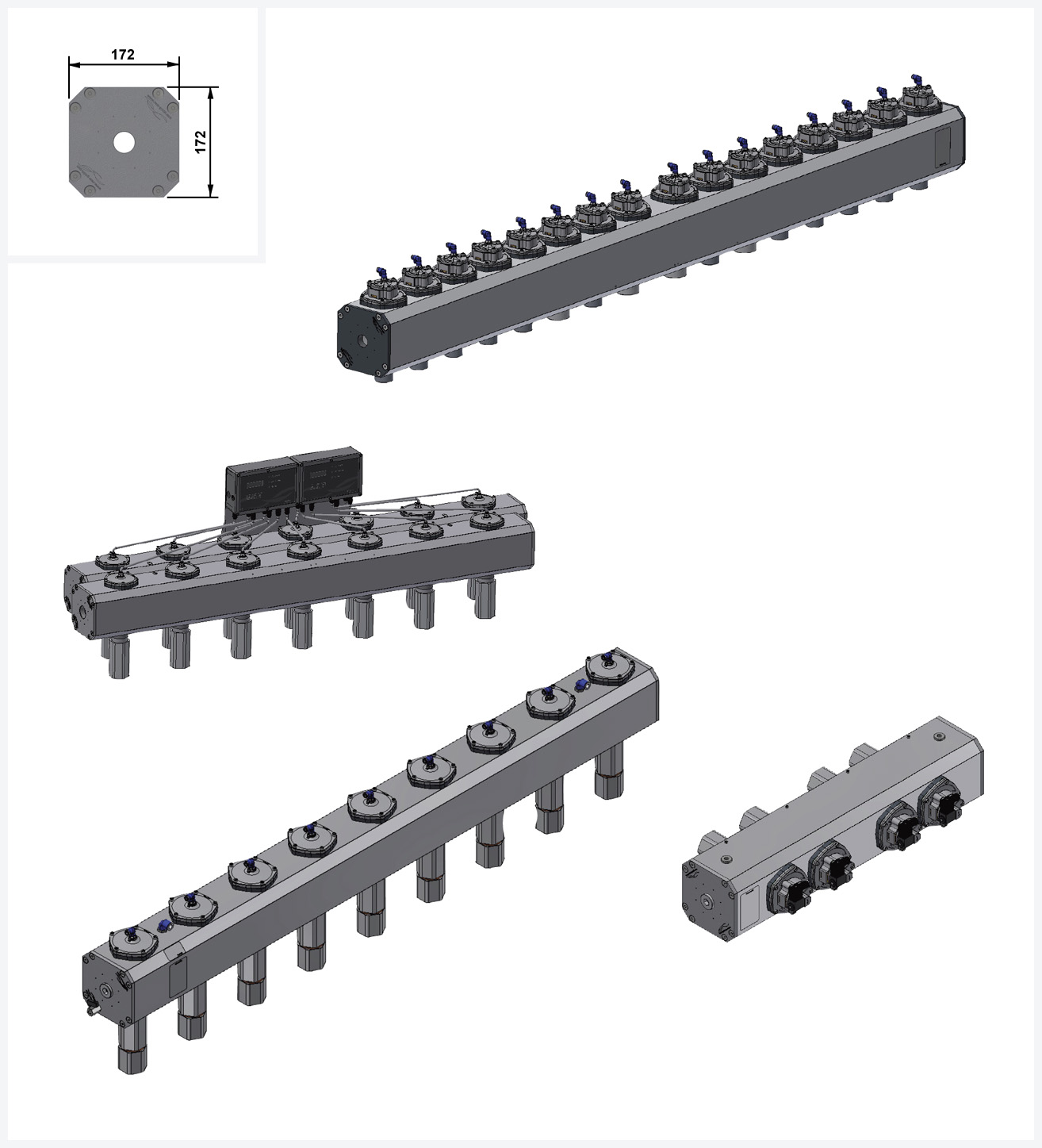

ST148-DN 20 / -DN 25 VR

Purge gas tank system with 90° angle diaphragm valves VR-DN 20 / 25

- Aluminium purge gas tank system according to pressure equipment directive 2014/68/E

- Design for screwed on VR valves with variable distances on one side or both sides

- High pressure pulse thanks to flow-optimized design of the VR valves

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Filter controllers or valve boxes can be directly attached to the aluminium section

- Various connection options and accessories for tank filters and valve outlet purge lance

- 5000 mm maximum length of the aluminium section

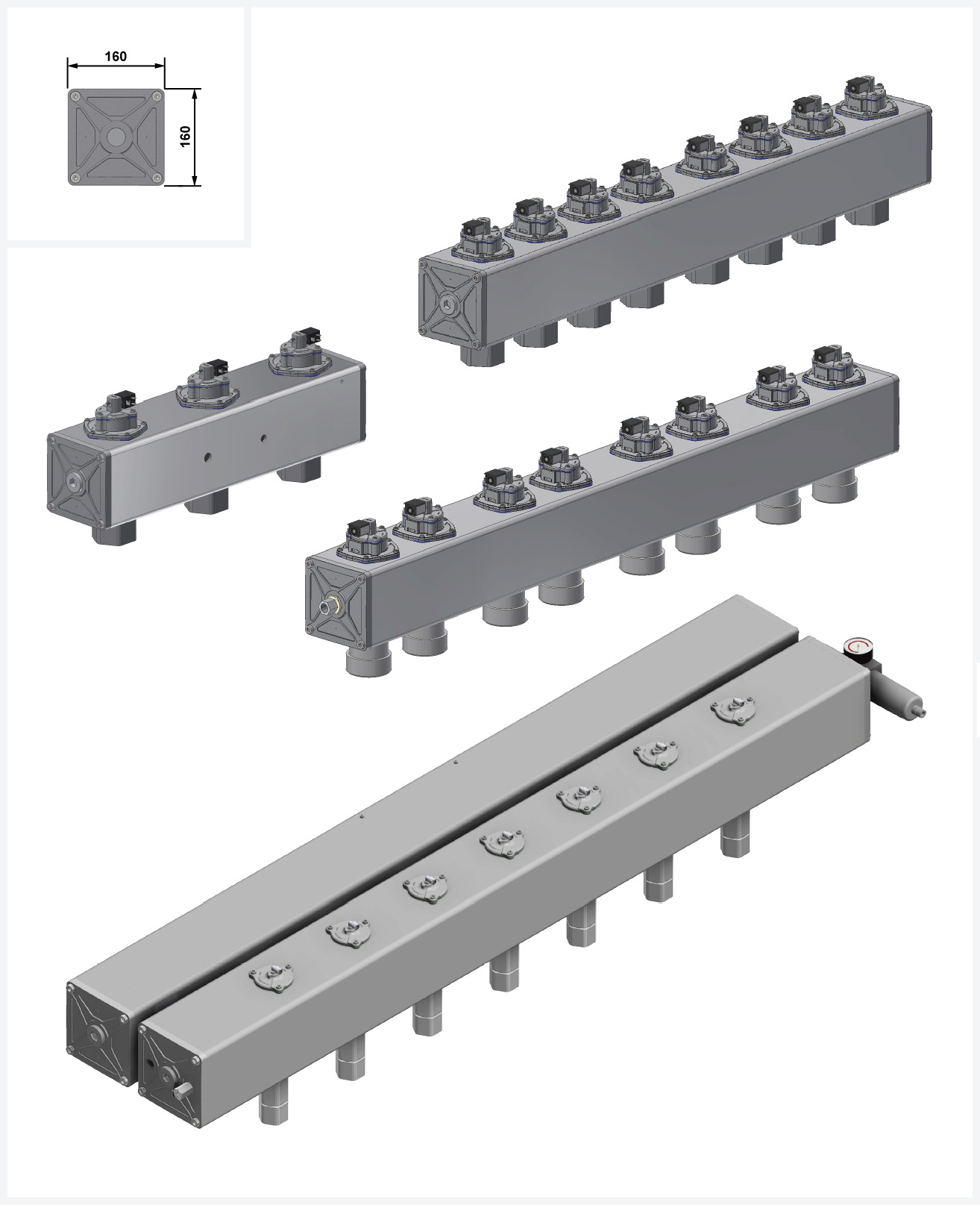

ST148-DN 20 SD / -DN 25 SD

Purge gas tank system with integrated diaphragm valve SD (small distance), min. 55 mm valve spacing

- Aluminium purge gas tank system according to pressure equipment directive 2014/68/EU

- Design for through valves with variable valve spacing

- through staggered valve arrangement allows small distances (SD) especially for pocket filters

- Very high pressure pulse through straight valve guide

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Filter controllers or valve boxes can be directly attached to the aluminium section

- 4000 mm maximum length of the aluminium section

ST148-DN 20 / -DN 25

Purge gas tank system standard design with integrated diaphragm valve, min. 75 mm valve spacing

- Aluminium purge gas tank system according to pressure equipment directive 2014/68/EU

- Design for through valves with variable valve spacing

- Very high pressure pulse through straight valve guide

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Filter controllers or valve boxes can be directly attached to the aluminium section

- 5000 mm maximum length of the aluminium section

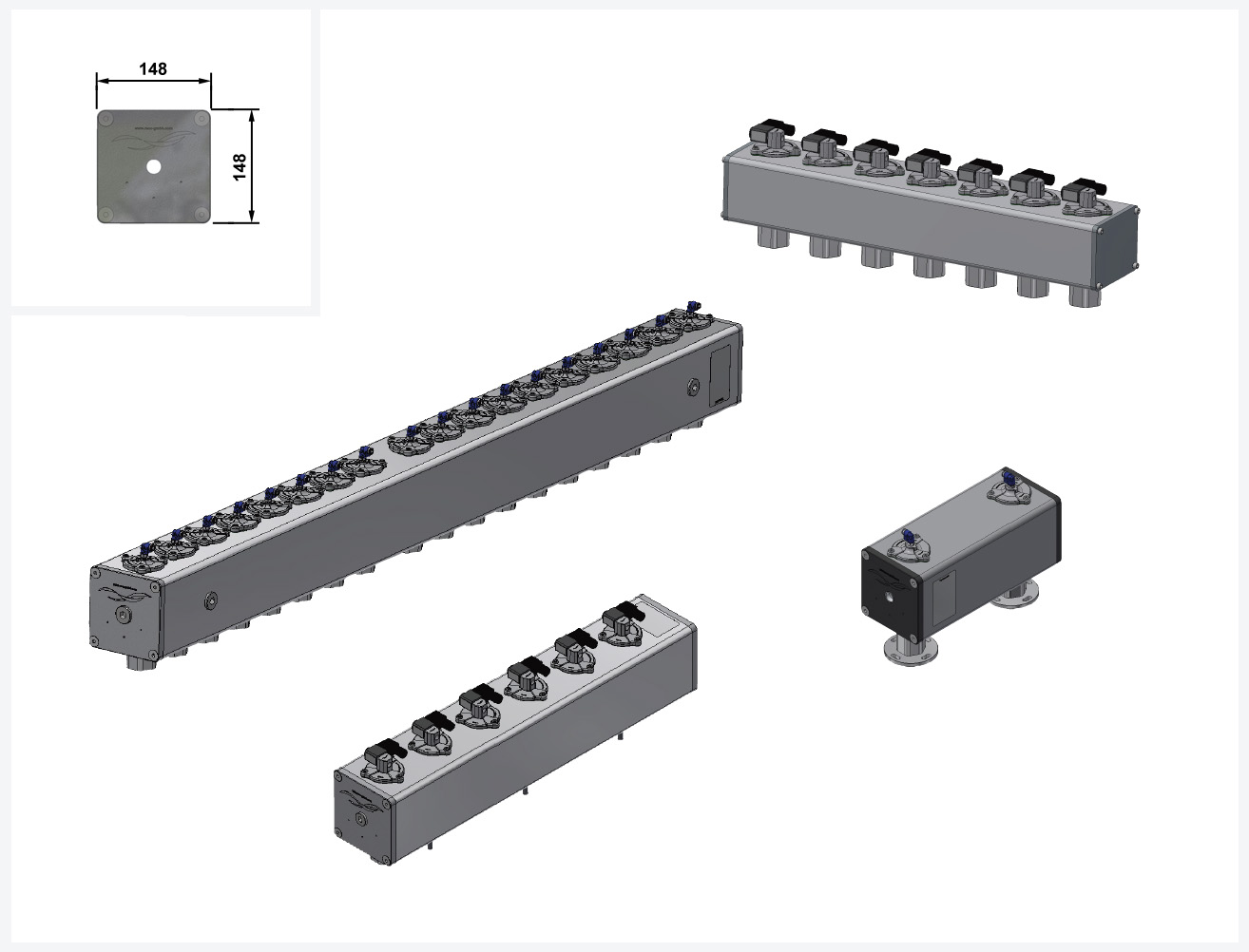

ST160-DN 25 / -DN 40 VS / -DN 50 VS

Purge gas tank system with integrated diaphragm valve, DN 25 directly operated / DN 40 and DN 50 pilot operated

- the new ST-160 profile is ASME-compliant, Di < 150 mm

- one aluminium section for all valve sizes DN 25 – DN 40 VS – DN 50 VS

- different valve sizes are possible in one purge gas tank

- Aluminium purge gas tank system according to pressure equipment directive 2014/68/E

- very high pressure impulse by direct mounting of the valves in the aluminium section

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Filter controllers or valve boxes can be directly attached to the aluminium section

- 5000 mm maximum length of the aluminium section

- Volume increase by flanged second tank – also ASME-compilant

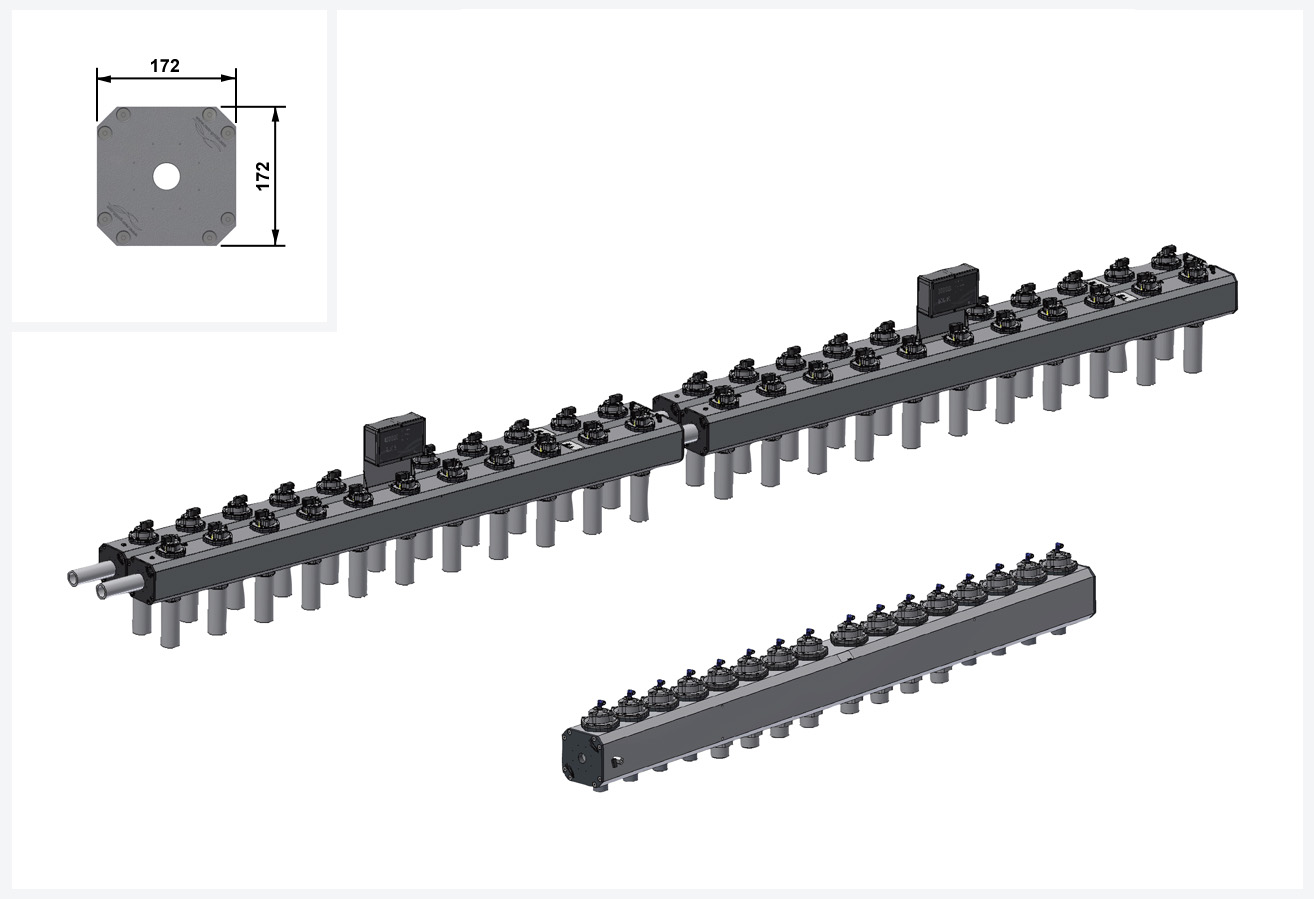

ST172-DN 40 VS

Purge gas tank system with integrated diaphragm valve, pilot operated

- Aluminium purge gas tank system according to pressure equipment directive 2014/68/EU

- with DN-25 pilot operation

- Design for through valves with variable valve spacing

- Very high pressure pulse through straight valve guide

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Filter controllers or valve boxes can be directly attached to the aluminium section

- 4000 mm maximum length of the aluminium section

ST172-DN 50 VS

Purge gas tank system with integrated diaphragm valve, pilot operated

- Aluminium purge gas tank system according to pressure equipment directive 2014/68/EU

- with DN-25 pilot operation

- Design for through valves with variable valve spacing

- Very high pressure pulse through straight valve guide

- TPE-E Power Reflex diaphragm with very short pressure rise and reflecting closing function

- Filter controllers or valve boxes can be directly attached to the aluminium section

- 4000 mm maximum length of the aluminium section

Solenoid valves NG4 / N4,5

Solenoid valves for electrical control of the diaphragm valves

- Quick venting solenoid valves for the control of diaphragm valves

- Flow-optimized design for large venting cross sections

- Hose/pipe connection by plug-in push-fit nipples on the valve body

- Easy electrical connection by flat-pin plugs

- Push-through system for easy and quick wall mounting of the valves

- Mounting in valve boxes, filter controllers and switchgear

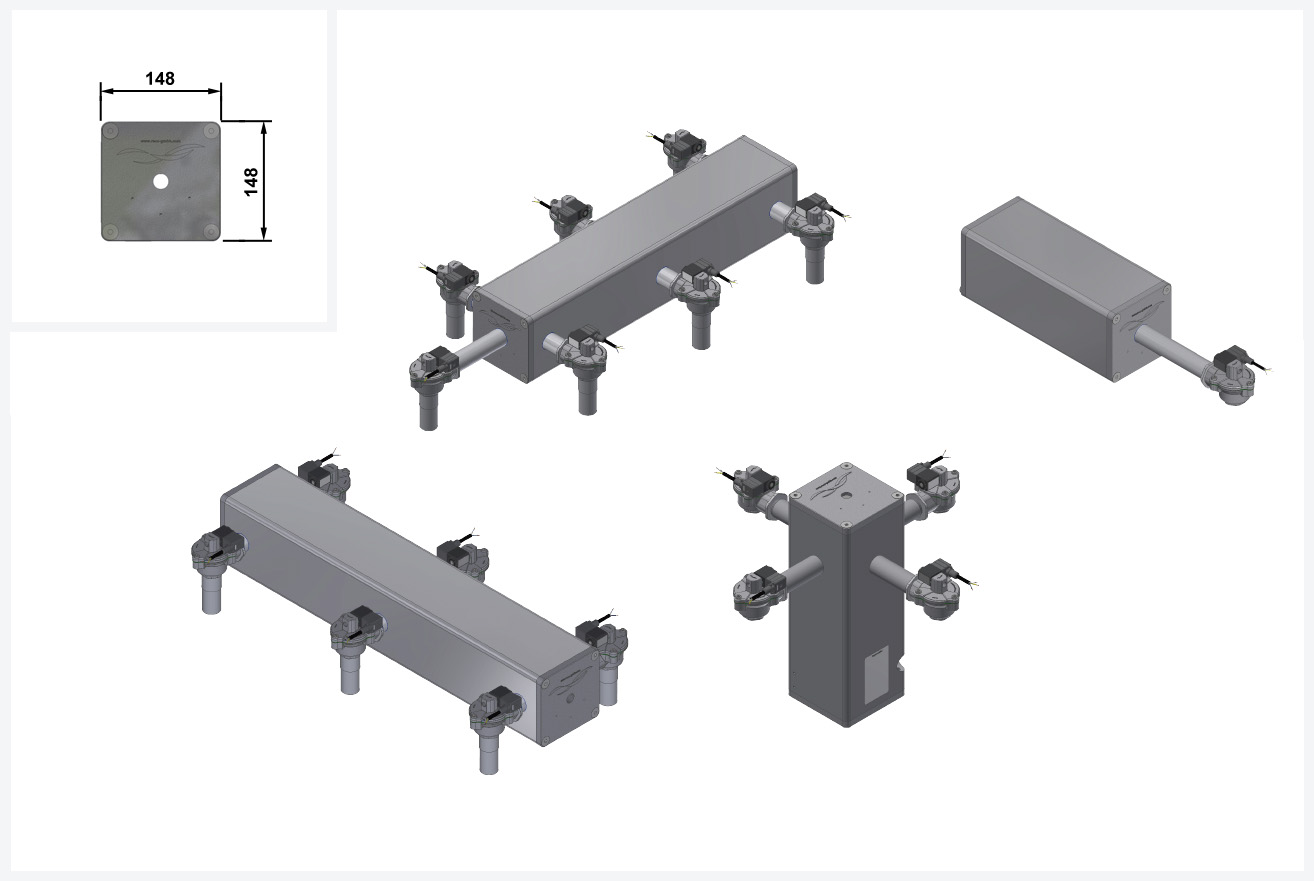

V-Box aluminium / plastic

Valve boxes with solenoid valves and control components for the control of the diaphragm valves and purge gas tank systems

- Valve boxes for the central arrangement of the control valves on the flushing gas tank system

- Valve island versions with R-IMC-Bus / R-IMC NET and/or Profibus / Profinet, see separate catalogue for RECO MATIC control systems

- Flexible use and easy installation independent of the flushing gas tank design

- Explosion-proof versions-Box —-

- System component for RECO flushing gas tank systems

Components

Accessories for valve technology, filter regulators, threaded unions, flanged joints, support plates, connection and joining components for VR valves and purge gas tank systems

- Serienteile aus RECO Aluminium-Strangpressprofilen für schnelle und Series parts from extruded RECO aluminium sections for quick and

optimal solutions - Customer-specific designs based on existing sections

- Mounting brackets for valve boxes and filter controllers

- Commercial pneumatic components in various packing units